Global maritime transport has traditionally relied on marine and heavy fuel oils (HFO) for propulsion. Whilst these fuels are cost-effective and bunkering widely available worldwide, they produce harmful emissions. As a result, regulations and laws are being put in place to limit ship emissions and how we can use LNG as Marine Bunkering Fuel

1 Overview: LNG as Marine Bunkering Fuel

Global maritime transport has traditionally relied on marine and heavy fuel oils (HFO) for propulsion. Whilst these fuels are cost-effective and bunkering widely available worldwide, they produce harmful emissions. As a result, regulations and laws are being put in place to limit ship emissions.

With fleet owners looking for alternative solutions, Liquefied Natural Gas (LNG) has been increasingly adopted as a cost-effective alternative marine fuel in order to reduce emissions.

This form of propulsion has been used on LNG carriers for decades (using the boil-off gas from LNG onboard tanks) with about 400-500 in operation today (2017). But it was only in 2000 that a non LNG carrier first utilised LNG as bunkering fuel.

Since then, this market has grown rapidly, with over 100 LNG fuelled vessels (that are non LNG carriers) in operation, and an equal amount on order (2017).

2 LNG as Marine Bunkering Fuel: Emissions Regulations

The International Maritime Organisation (IMO) developed the Prevention of Marine Pollution Convention (MARPOL), which looks to protect the marine environment. MARPOL is the primary treaty that covers ship pollution internationally. The latest annexe, which came into force in May 2005, aims to regulate air pollution emitted by ships, including Nitrogen oxides (NOx), Sulphur Oxides (SOx) and other volatile organic compounds. It also requires the establishment of Emission Control Areas (ECAs), which are areas in which there are stricter controls to minimise airborne emissions.

The established ECAs are:

1. Baltic Sea area

2. North Sea area

3. North American area

4. The United States Caribbean Sea area (around Puerto Rico and the United States Virgin Islands)

In October 2016, the IMO established that a global 0.5% (mass by mass) sulphur limit will apply to fuel oil used by ships from 1 January 2020. Within the ECAs, a sulphur limit of 0.10% m/m has applied since 1 January 2015.

The limits for SOx are:

| Outside an ECA | Inside an ECA | ||

| Prior to 1 January 2012: | 4.50% m/m | Prior to 1 July 2010: | 1.50 % m/m |

| From 1 January 2012: | 3.50% m/m | From 1 July 2010: | 1.00 % m/m |

| From 1 January 2020: | 0.50% m/m | From 1 January 2015: | 0.10 % m/m |

This implies that vessels have to either use a compliant fuel or switch over from any high sulphur content fuel to a compliant marine fuel prior to entry into an ECA.

There will be strict enforcement and inspections, particularly in European ports. Fines will likely be used to counterbalance the economic benefits that ignoring the limits would entail.

Current and Future Sulphur Regulations

3 Why LNG as Marine Bunkering Fuel

LNG primarily consists of methane (CH4), which reduces carbon dioxide (CO2) emissions by up to 30% when used as a fuel. Less nitrogen is present in the combustion process due to the compression rations and methane combustion temperatures, reducing the production of nitrogen oxides (NOx) by up to 85%. LNG has no sulphur content, thereby sulphur (SOx) emissions by 100%. LNG is non-corrosive, non-toxic and non-flammable in liquid form. LNG is also comparable in cost to traditional marine fuels (although dependent on the LNG bunkering infrastructure available to the vessel) and has the benefit of a reduction in operating costs.

Increasing stringent regulations will require additional investments to reduce SOx and NOx emissions. Whilst LNG has a high investment cost, the associated operational savings can be significant, depending on the fuel price. Alternatives, such as treatment systems for the exhaust gas, also add significantly to the cost of the ship. These systems also require additional space and can increase fuel consumption by 2-3%. The use of LNG, which is sulphur-free, is, therefore, a viable solution to meeting the emission limits.

4 LNG as Marine Bunkering Fuel: Infrastructure required

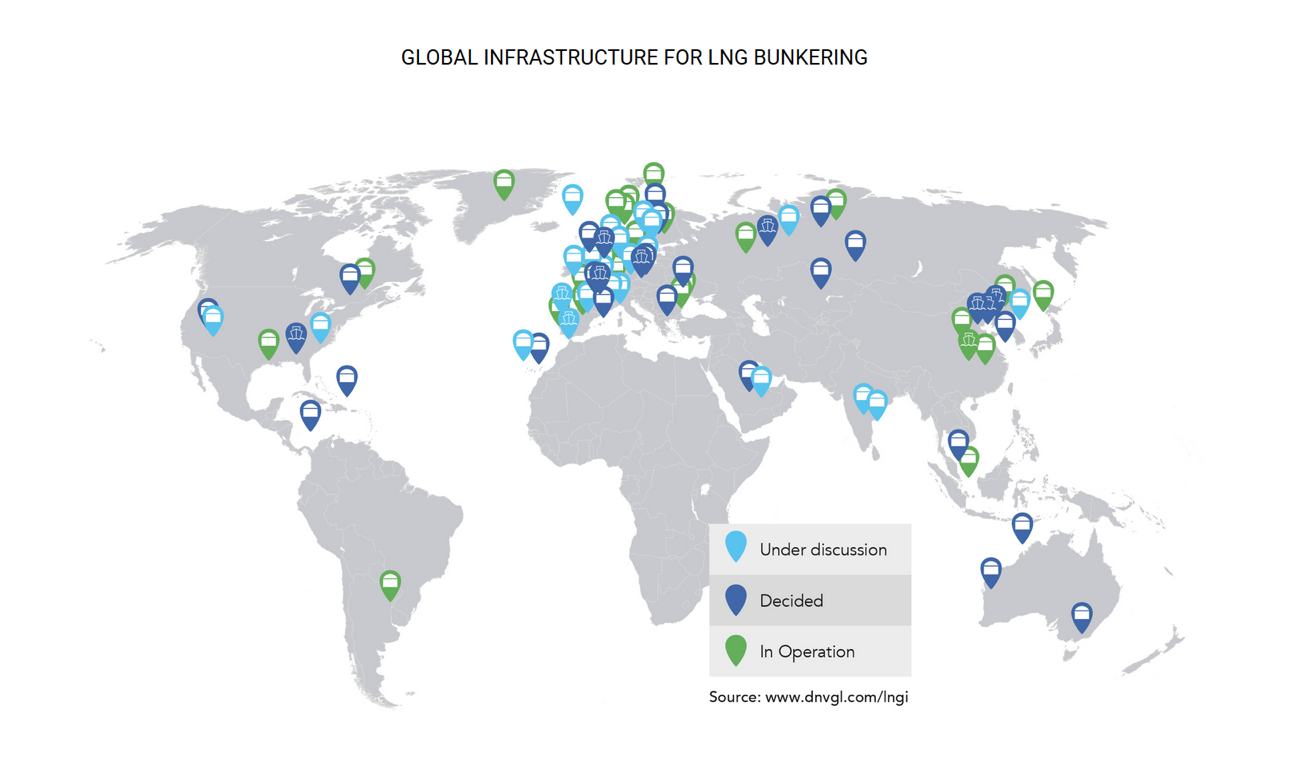

LNG is widely available, with 20 countries exporting the fuel and 35 importing it. Existing port infrastructure is however focussed on these import and export activities, which does not cater for small-scale refuelling of vessels. Facilities that provide for the refuelling of ships at ports is termed bunkering and is increasingly being provided worldwide. LNG bunkering infrastructure is currently concentrated heavily in Europe.

LNG is imported in large LNG tankers, with common storage capacities ranging between 80 000 and 260 000 cubic metres. These vessels are large and cannot be used to import to smaller terminals. Smaller LNG feeder vessels, ranging in size from 7500 to 20000 cubic metres are used to supply the smaller terminals in ports. Integrating transferring facilities with existing ports can be difficult, and bunker vessels are therefore frequently used to transfer LNG to vessels.

Bunkering requires storage and transfer facilities. LNG can be transferred to vessels from a stationary shore-based tank by pipeline, or from mobile units in the form of vessels (ship-to-ship transfer) and trucks (truck-to-ship). The mobile units require their own LNG supply source in the form of strategically placed terminals. The ship-to-ship transfer is the transfer of LNG from a vessel or barge, with LNG as cargo, to another vessel to use as fuel. It can be done at sea or at a port. It allows for large volumes of LNG to be transferred. The development costs can, however, be high, and requires space to accommodate the vessels in a port. The truck-to-ship transfer is flexible and has a lower cost, but the quantity of fuel that can be transferred is smaller and the loading is lower. The ship-to-shore transfer is desirable for large volumes and has a faster turnaround time. It, however, requires a large investment to build the facilities in ports. LNG can also be supplied in standardised containers and loaded on the ship directly.

LNG bunkering is currently available in 60+ locations, with further 70+ facilities in planning stages. There will be six LNG bunker vessels in operation by the end of 2017, which will enable ship-to-ship bunkering in Northwest Europe and the USA.

5 LNG as Marine Bunkering Fuel: Vessel considerations

5.1 Storage of LNG

The design of LNG storage tanks has to adhere to the various codes. The type, size and tank locations are important considerations. LNG requires approximately four times the storage space required for conventional fuels, so an optimum layout is important. The location of tanks is important from a safety perspective, with their position being restricted by IMO guidelines. The tanks have to be well insulated, and a surrounding safe area is required in case of accidental spillage.

5.2 Handling boil-off gas

The boil-off gas increases the pressure in the storage tanks. The tanks are therefore designed to handle higher pressures and are fitted with pressure relief valves to allow venting of gas to the atmosphere if the pressures become excessive. Venting gas is only allowed in emergency situations and is not a method for pressure control. Venting of the gas is also undesirable from an economic and environmental perspective. The more volatile components of LNG (nitrogen and methane) boil-off first, changing the composition and quality of LNG over time. This is known as ageing.

Some methods to manage the boil-off gas are:

- Reliquefaction of the gas to LNG. This can be by a direct system, where the gas is compressed and condensed before being returned to the tank. An indirect system condenses or cools the gas with an external refrigerant, without being compressed.

- Burning off the excess gas in a thermal oxidiser. On an LNG-fuelled vessel, this is primarily done by feeding the excess gas to the engines. If the boil-off gas exceeds the rate at which it can be used, the gas can be fed to a gas combustion unit, which burns the gas in a controlled matter. No useful energy can be recovered from burning the gas in this method.

- Allowing the pressure to accumulate

- Cooling the LNG

- Using the boil-off gas as energy for ship operation. The gas can also be used to produce steam or hot water in boilers.

5.3 Engines

The first LNG fuelled vessels that were non-LNG carriers utilised gas-only engines. Dual-Fuel (DF) engines can run on gas or on diesel fuel. Engines can also run on a combination of gas and diesel, where approximately 70% of energy is provided by gas and 30% by diesel. This is an option that is suited to refits of engines which cannot be converted to dual-fuel. The most prominent manufacturers of engines are currently Wärtsilä, MAN, Caterpillar, HiMSEN, Siemens, Mitsubishi or Rolls Royce.

LNG ready vessels make allowance for the vessels to be converted to LNG-fuelled vessels in the future. Measures can include structural reinforcements and the correct choice of material to support future LNG tanks, preparations for future gas fuel systems and installation of machinery which can be converted to gas fuel (or is already capable of burning gas fuel). This simplifies a later conversion. An LNG ready ship is suitable where the current market conditions and/or LNG availability does not make current commercial sense. The additional investment can then be made when the commercial situation is favourable. Being LNG ready therefore increases the flexibility of the vessel, extends its lifetime and can increase its second-hand value.

It is relatively straightforward to convert existing diesel engines for operation on LNG. This process typically involves changes to the cylinder heads and liners, pistons and rings, connecting rods and turbochargers. Gas rails and admission valves, together with a pilot fuel system were also required, as well as the fitment of storage tanks.

5.4 LNG as Marine Bunkering Fuel: Fuel supply

A fully redundant fuel supply system is required by IMO regulations. Where gas-only is used, the LNG has to be stored in two or more tanks of approximately equal size. Dual fuel engines are allowed to have a single storage tank of LNG, with liquid fuel as a backup.

5.5 LNG as Marine Bunkering Fuel: NG safety

LNG brings some unique safety considerations when compared with heavy fuel oils. LNG is non-flammable, due to a lack of oxygen in the liquid. However, when LNG vapourises, the resulting natural gas is flammable when it is in a 5% to 15% (by volume) mix with air. Natural gas is odour- and colourless, and LNG cannot be odourised, making it hard to detect without equipment.

The low temperature of LNG (-162 degrees Celsius) can result in severe injuries from direct body contact. It can also render normal ship steel very brittle and it can fracture when exposed to LNG.

Due to the large energy content contained in the LNG storage tank, the tank has to be protected. This entails protecting it from possible ship collision and grounding, mechanical impacts, external fires, and BLEVE (boiling liquid expanding vapour explosion).

Despite the risks involved, LNG has proved to be a safe choice of fuel and in marine transport. The IMO guidelines and IGF code have ensured that the design and operation of ships follow best practise principles to reduce the risks.

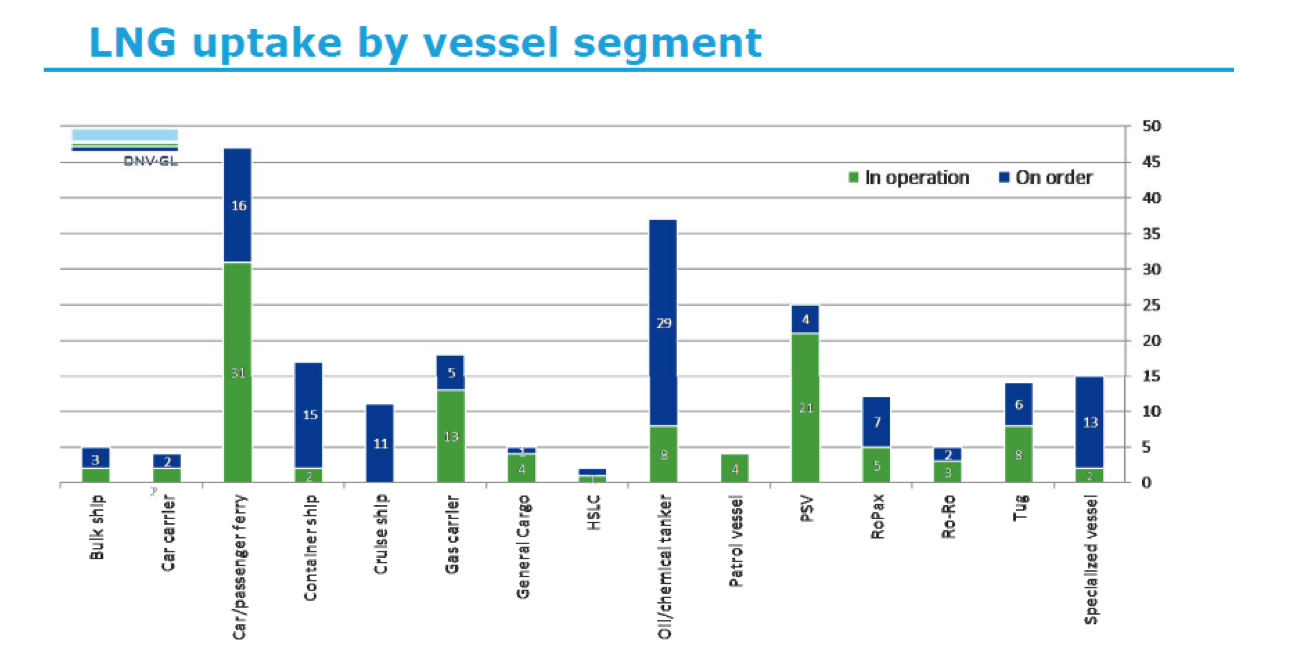

6 LNG as Marine Bunkering Fuel: Market

The first LNG-fuelled vessel that was not an LNG carrier was the Norwegian ferry Glutra, which came into service in 2000. Within three years, two oil and gas platform supply vessels (PSV) also began operation in Norway. Since then, there has been an increasing rate of new LNG fuelled vessels coming into service. Norway’s tax on NOx, introduced in 2007, and the availability of LNG in the region, helped spur the introduction of LNG-fuelled vessels there. Until 2013, all 37 LNG fuelled vessels (bar one) were based in Norway. The formation of ECA’s in Europe and North America, and a steep increase in the price of heavy fuel oils, led to more consideration being given to LNG as a marine fuel. As of May 2017, there are 106 vessels in operation, with an additional 115 on order.

There has also been a diversification in the type of vessels that are LNG-fuelled, and the areas of operation are expanding.

The gas market has seen a recent boom, partly due to the boom in non-traditional (shale) gas production, which utilises the hydraulic fracturing (fracking) process.

7 LNG as Marine Bunkering Fuel: Organisations

The European Union is actively promoting the use of LNG and is funding projects to improve the supply of LNG. Current EU policy requires at least one LNG bunkering port in each member state.

The Society for Gas as a Marine Fuel (SGMF) was established in 2014 following a decision by the Society of International Gas Tanker and Terminal Operators (SIGTTO). SGMF is an NGO which aims to promote the safe and responsible operation of LNG-fuelled vessels and to develop guidelines for best practice amongst its members. Multi-sector industry organisations, such as SEA/LNG (founded in 2016), are also being formed to create coalitions aimed at promoting LNG as a marine fuel. SEA/LNG brings together key players, including shipping companies. LNG suppliers, LNG bunkering companies, ports, engine suppliers etc.

8 References

DNV-GL, 2014, LNG as ship fuel No 01 2014.

DNV-GL, 2015, In Focus – LNG as ship fuel No 01 2015.

Royal Academy of Engineering, 2013, Future Ship Powering Options: Exploring alternative methods of ship propulsion.

International Maritime Organization, 2016, Studies on the feasibility and use of LNG as a fuel for shipping

Rutkowski, 2016, Study of New Generation LNG Duel Fuel Marine Propulsion Green Technologies, The International Journal on Marine Navigation and Safety of Sea Transportation

Dorde Dobrota, Branko Lalić, Ivan Komar, 2013, Problem of Boil-off in LNG Supply Chain, Transactions on maritime science

9 Further Reading

International Maritime Organisation

International Maritime Organisation – 2020 Global Sulphur Limit

IMO Studies On The Feasibility and Use of LNG as a Fuel for Shipping

IMO – MARPOL International Conventional for The Prevention of Pollution from Ships

SEA\LNG is a multi-sector industry coalition, created to accelerate the widespread adoption of liquefied natural gas (LNG) as a marine fuel. Our vision is of a competitive global LNG value chain for cleaner maritime shipping by 2020

To all knowledge

To all knowledge